In the same section

-

Share this page

Holographic sensor for potentially explosive atmospheres (ATEX) monitoring [Technology Offer]

The technology in a nutshell

Our invention performs in time a 3D imaging process within a volume to allow to count particles, even fastly moving, and to measure their sizes to determine the corresponding statistics on the cloud and concentrations.

State of the art

A potentially explosive atmosphere exists when dusts present in mixture of air gases, vapors, mists can ignite under certain conditions that often happen in industrial environments. Currently, dust detectors are basically based on three main methods: (i) the measure of the reduction in the light intensity of a beam incident on a photosensitive cell when particles pass through the light beam. (ii) The use of light scattering (Dynamic Light Scattering). (iii) The measurement of the electrostatic induction created by the passage of particles in the vicinity of an electrode. When charged particles pass by or strike the probe, the induced electric current generates a signal that is digitally processed.

The Invention

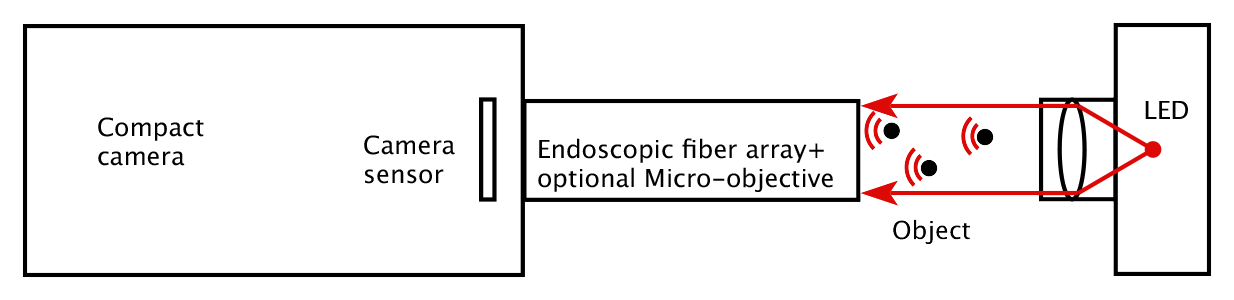

The patent claims a compact holographic sensor which consists in using a network of endoscopic fiber array coupled to the camera sensor. The object hologram that is incident on the free entry window of the fiber array, away from the camera, is directly propagated and imaged onto the camera's sensitive sensor. We can thus achieve holographic recording of experimental volumes inaccessible by other techniques.

Fig 1.a: scheme of the prototype

Key advantage of the technology

- Counting particles and identifying their 3D positioning within a fluctuating cloud

- Continuous measurement and monitoring of the size and distribution of particles and their concentrations for the particle explosive size range 4 µm - 500 µm

- Establishment of the relevant statistical figures about the cloud

Potential application

Equipment and protective sensors intended for potentially explosive atmospheres (ATEX) monitoring cover the following market sectors:

- Manufacture of food products

- Mining and coal industry

- Manufacture of wood and wood products

- Manufacture of metal products

- Pharmaceutical Industry

- Chemical and petrochemical plants

The industrial equipment of potential applications is for example: silos, dedusting systems, spray dryers, filters and collectors, mills/grinders

Technology readiness level

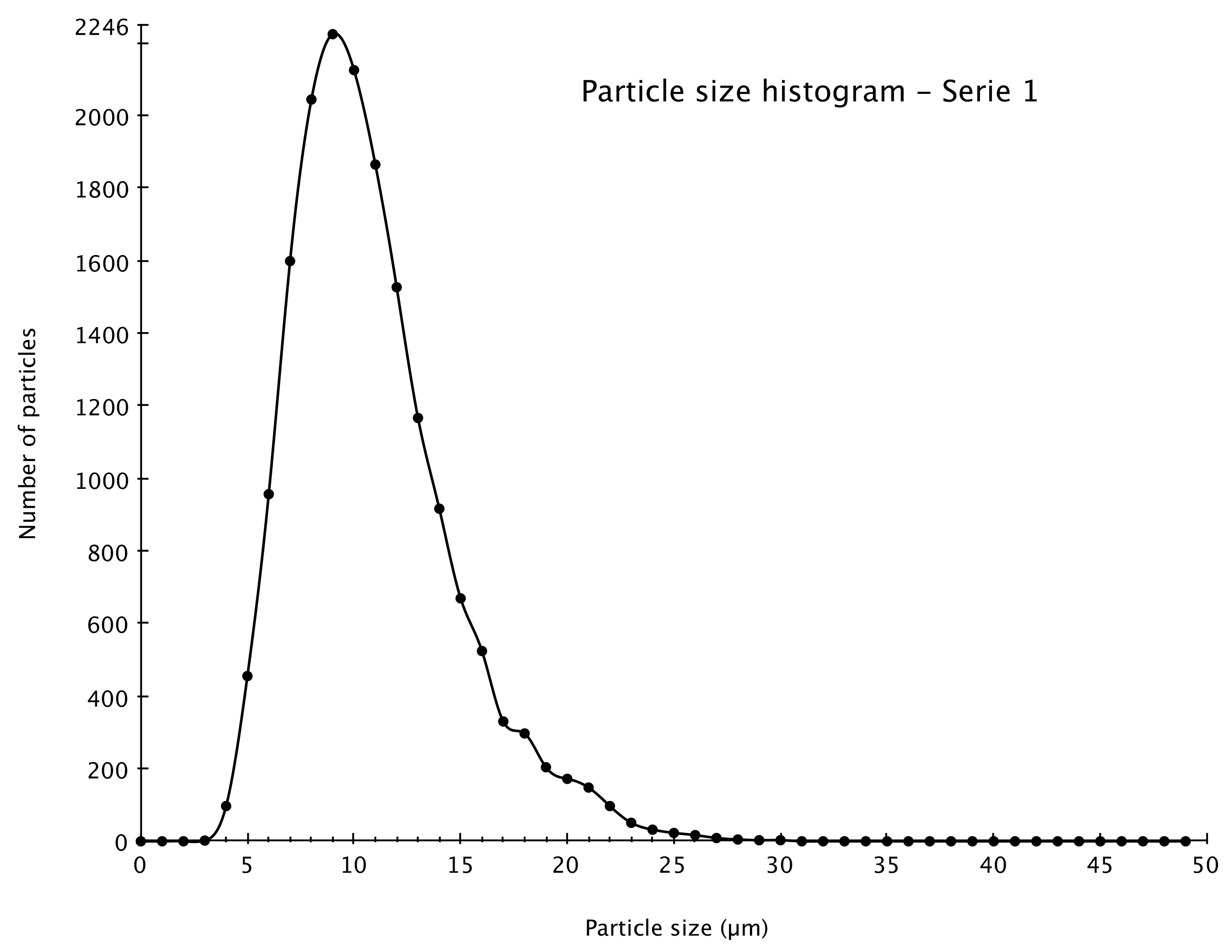

A prototype of the holographic sensor was build and tested in the laboratory on fine sugar dust clouds that are potentially explosive in industries and that are representative of dust explosive phenomena. The software were developed to process the recorded holograms and to extract the particle parameters (size, 3D position). The holographic sensor was able to monitor the evolution of the fine sugar particles concentration in a fluctuating cloud and to provide image of each particle in one or two directions. It allows to obtain the particle dimension distribution in a volume during the time with a resolution of 4µm. An example of sugar particle distribution is shown in figure 1.b.

Fig 1.b: measured size distribution of fine sugar dust in a cloud

The team

The research activities of the Microgravity Research Centre of ULB (MRC) are oriented in fluid physics and advanced optical methods for fluid physics, biomedical and environmental researches and applications. The research projects of MRC are both fundamental and applied and can cover theoretical, numerical and experimental aspects. In those ones, the MRC has developed important skill for experiments in space and microgravity.

The laboratory is pursuing developments in optical metrology and proposes a set of new 3D measuring instruments based on digital holography microscopy (DHM).

Historically, the MRC was one of the first laboratories in the world to develop this type of instrumentation. The MRC has made a series of innovations reported and protected by patent applications.

The inventors

He developed with his collaborator, Dr. Catherine Yourassowsky, digital holographic microscopy with partial coherent illumination and its combination with fluorescence microscopy, differential digital holographic microscopy and color digital holographic microscopy, protected by granted patents.

The technologies were developed on numerous biomedical, environmental and spatial applications.

Keywords

- ATEX Equipment and protective systems

- Dust detectors

- Holographic sensor

- Continuous monitoring

Collaboration type

- Licence agreement

- R&D collaboration

IP status

WO2014037575A1

Granted in the USA (US 9,599,959 B2 – 2017), under review in Europe

Priority Date: 10/09/2012

Inventors

- Pr Frank Dubois

- Dr Catherine Yourassowsky

Contact

ULB Research Department

Arnaud Quintens

Business developer

+32 (0)2 650 96 78

arnaud.quintens@ulb.be